SIEBFABRIK were one of the first companies in Germany to develop and supply screens, screen belts and technical mesh for producing special non-woven fabrics last year. These are essential for coveralls and masks. SIEBFABRIK’s expertise is also put to use in the rapid Covid-19 tests. The substrates for evaluating the results consist of several different non-woven fabrics which are manufactured on SIEBFABRIK’s screens. A chemical reaction clearly indicates whether the test is positive or negative. “We are pleased that we can use our knowledge and our products to help increase protection against coronavirus,” says Managing Director Dipl.-Ing. Christoph Leppla. Screens and screen belts made of synthetic and metal fabrics from SIEBFABRIK run completely reliably and faultlessly on their customers’ high-tech production machines.

Very thin, extremely tear-resistant and breathable special non-woven fabrics

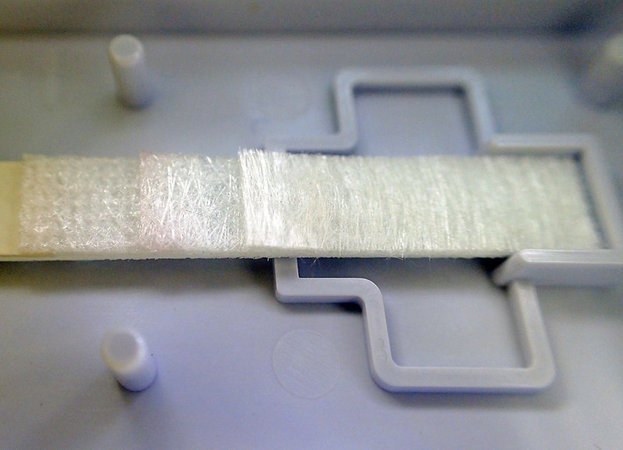

The special non-woven fabrics for coronavirus protection consist of synthetic fibres or extruded, melted polymers which are very thin, light, extremely tear-proof and breathable. Thus they prevent penetration of bacteria and viruses and offer high resistance against water, friction and ageing. These special non-woven fabrics are manufactured using the melt-blown process. SIEBFABRIK’s screen belts play a key role in this: Similar to the spun bond technology, the melt-blown process involves first melting the polymers and then spraying them using spinnerets as microfibres with a size of approximately 1 micrometre onto the collector belt. As SIEBFABRIK’s collector belts are resistant to high temperature, the microfibres are deposited homogeneously, creating the required surface and porous structures.

Close collaboration with research institutes

Different requirements always arise during deposition and formation as well as the transport of these special non-woven fabrics, and we are able to respond flexibly and with maximum reliability,” says Dipl.- Ing. Christoph Leppla in regard to his team’s expertise. SIEBFABRIK is working closely on research projects with institutes such as the Deutsches Institut für Textil- und Faserforschung Denkendorf (DITF – German Institute for Textile and Fibre Research), the Fraunhofer-Institut für Techno- und Wirtschaftsmathematik (ITWM – Frauenhofer Institute for Industrial Mathematics) and Nanoval GmbH & Co. KG (Berlin).

New production hall optimises availability

Customers appreciate the rapid availability and supply as well as the quality of SIEBFABRIK’s products. “Time is a really important factor, especially when it comes to the impact of the coronavirus pandemic. Our customers’ machines are often working around the clock, so there can’t be any interruptions to the supply chain,” adds Dipl.-Ing. Christoph Leppla. The completion of the new 2,500 m2 production halls at the company’s premises in Mössingen-Öschingen ensures lean management with associated production process for further product innovations too.

Excellent service reliability

SIEBFABRIK places great importance on reliability, including in relation to service: Qualified fitters for maintenance, installation, fitting of new covers and repair of cylinder moulds and belts are on site as quickly as possible. “Time isn’t just money, it plays a key role in the health of many people. Our service ensures that our customers’ production processes are stable and run reliably – and economically of course, all around the world,” says Dipl.-Ing. Christoph Leppla in regard to a key aspect of the company’s philosophy.