Special non-woven fabrics: SIEBFABRIK is the leading supplier for reliable protection

Special non-woven fabrics are used as the primary material for personal protective equipment. Manufacturers of non-woven fabrics produce them on high-tech production machines and systems which need to be able to run reliably around the clock. And this is exactly where the technical mesh, screens and solutions from SIEBFABRIK Arthur Maurer GmbH & Co. KG, based in Mössingen-Öschingen prove essential. “Our screens, screen belts and bronze mesh ensure maximum product quality, a reliable, durable process and around-the-clock system availability when it comes to producing non-woven fabrics,” explains Christoph Leppla, Managing Director of SIEBFABRIK.

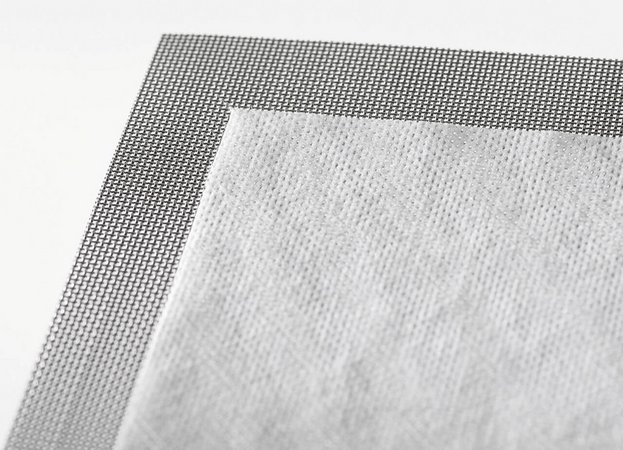

Non-woven fabrics for coveralls and masks: A special material made from the finest fibres

The material is a special plastic non-woven fabric which is very thin, light, highly tear-resistant and breathable. Depending on the design, it is highly resistant against water, friction, deterioration and prevents ingress of bacteria and viruses.

Screens/screen belts for manufacture using the thermal ‘melt-blown’ method

Special non-woven fabrics are produced using the melt-blown method. The SIEBFABRIK screen belts take on a crucial role here as process belts which function seamlessly and reliably. The melt-blown process (which is similar to spun bond technology) involves melting polymers. Spinnerets are then used to spray these as extremely fine, melt-spun microfibres (approx 1 micrometre in size) onto the collector belt. The SIEBFABRIK screen belts are resistant to high temperature and ensure that the microfibres are deposited homogeneously, creating the required surface and structure. As an innovative mesh manufacturer, SIEBFABRIK brings years of extensive industry, process and expert know-how to the table for the deposition, forming and transport of these special non-woven fabrics. SIEBFABRIK is carrying out research in conjunction with the Deutsche Institute für Textil- und Faserforschung Denkendorf (DITF – German Institutes of Textile and Fibre Research), the Fraunhofer-Institut für Techno- und Wirtschaftsmathematik (ITWM – Frauenhofer Institute for Industrial Mathematics) and Nanoval GmbH & Co. KG (Berlin).

Availability ensured thanks to production in Germany

“The screens are produced in Germany on modern precision looms,” explains SIEBFABRIK Managing Director Christoph Leppla. “There simply shouldn’t be any compromises, especially when it comes to high-tech applications. Specialists like us are a must. We have extensive expertise and are in charge of the entire production process so we can offer our customers maximum reliability and quality.” During the coronavirus crisis, it is extremely important to ensure availability and reliability of machines and systems to maintain supply capability and supply chains.

The company has ramped up production and is using predictive inventory management to ensure high supply capability and to meet the increased demand from customers. “We are now producing more, we have a buffer stock which will last a long time and are keeping our screens in stock. We have agreed call-up contingency for our products with our customers,” explains Christoph Leppla.

SIEBFABRIK is on the safe side when it comes to service: They keep a contingency of qualified fitters ready for their customers. They are protected and available for necessary call-outs, such as repair and installation, fitting of new covers and assembly/repair of cylinder moulds and belts. The company also takes all possible and necessary safety measures in-house and has drawn up codes of conduct to protect customers, suppliers and its own employee team – both field staff and in-house staff. “The aim of our service team is to keep our customer’s processes running. In a safe, long-lasting and economical manner,” stresses Leppla.