Good Wood

Resistant, productive, safe and economical: the suitable woven wire cloth for your process

Process belts for wood processing have to withstand high mechanical, thermal and chemical loads and must be protected against electrostatic charging in accordance with the ATEX standard. For the best possible trouble-free production reliability, we offer custom-tailored woven wire-cloth designs made of metal, synthetic or material combinations.

The screen belts are in demand in various applications and operational areas in the wood processing industry:

- Presses and drying systems

- Wood chip drying

- Production of wood chips

- Production of veneers

- Production of chipboard, MDF, OSB, fibreboard and multiplex panels

- Production of wood pellets and wood briquettes

The drying belts for belt dryers or press belts are designed in accordance with the process requirements. Depending on the working temperature, they can be made of stainless steel, polyester, PPS or PEEK, e.g. also with integrated bronze wire to protect against electrostatic charging.

Advantages of our screen belts

- Reliable, resistant and highly accurate – to meet all thermal and mechanical requirements

- Manufactured on state-of-the-art looms

- High process performance

- Exactly reproducible results

- Exactly defined individual mesh width/woven wire cloth opening/permeability, flow rate/retention capacity

- High lateral stability, optimum flatness, precise tracking

- High process speeds

- Optimised mechanical properties

- High physical and chemical resistance

- High thermal stability

- Electrostatic safety (ATEX)

- Easy cleaning

- Long life, high running performance

- Delivered ready to install

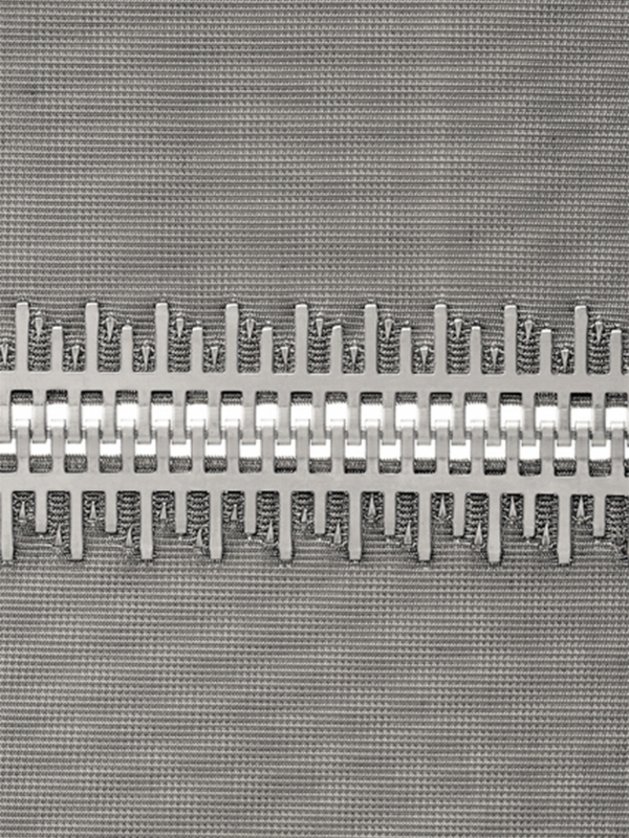

Twilled weave with a clipper seam

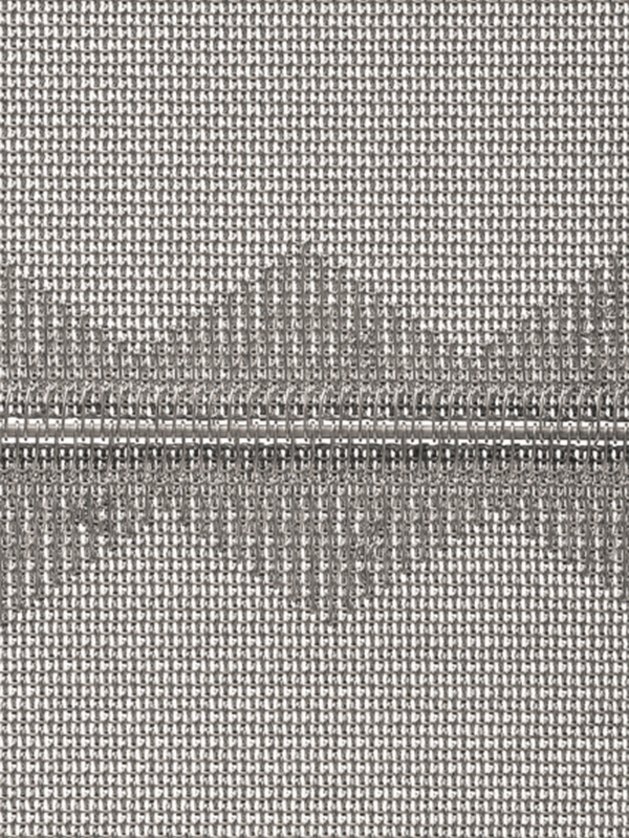

Polyester belt with antistatic wires

PPS belts with antistatic wires

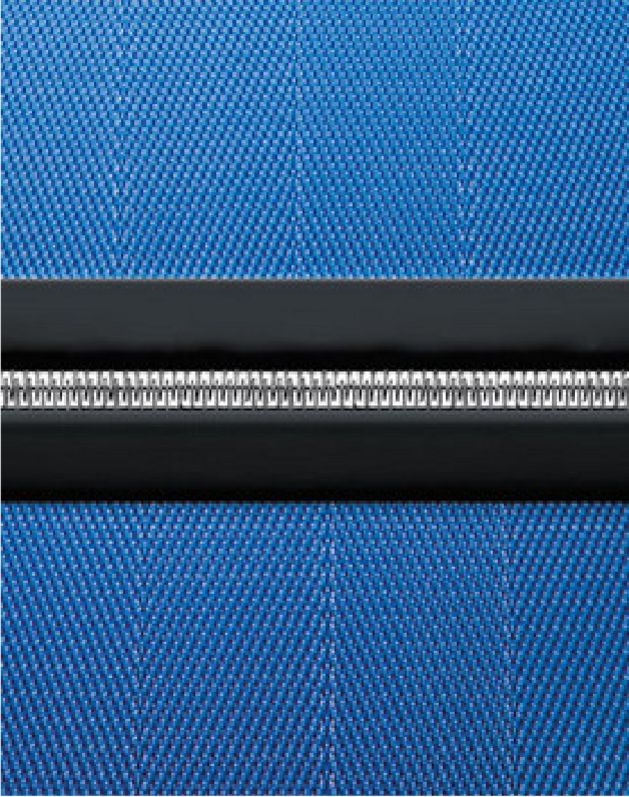

We have the right seam and border design for your belt.

Ask us for an individual consultation. Our engineers with comprehensive industry, process and procedural expertise are available to help you with advice and assistance. Trained technicians and service experts with world-wide, cross-industry experience are also there for you during on-site installation or repairs.