Hygienic and dynamic: Process belts

Continually safe and economical

Process belts – woven wire cloth that is continually used in a process - have to withstand a lot. In the food processing industry they are subjected to high mechanical, thermal and chemical loads. From -200 °C to over 1,000 °C. For process reliability and stability, the woven wire cloth and seam connections of the woven wire cloth ends must be optimally matched to the material and the application. And the design of the seams on the belt edges is just as important.

As a specialist for woven wire cloth with comprehensive industry know-how, SIEBFABRIK offers you process and conveyor belts optimal for the respective process for a broad range of requirements. Reliable, rugged and highly accurate. Manufactured in Germany – on state-of-the-art looms. The "long-distance runners" ensure the greatest possible fault-free production reliability for demanding food-related processes.

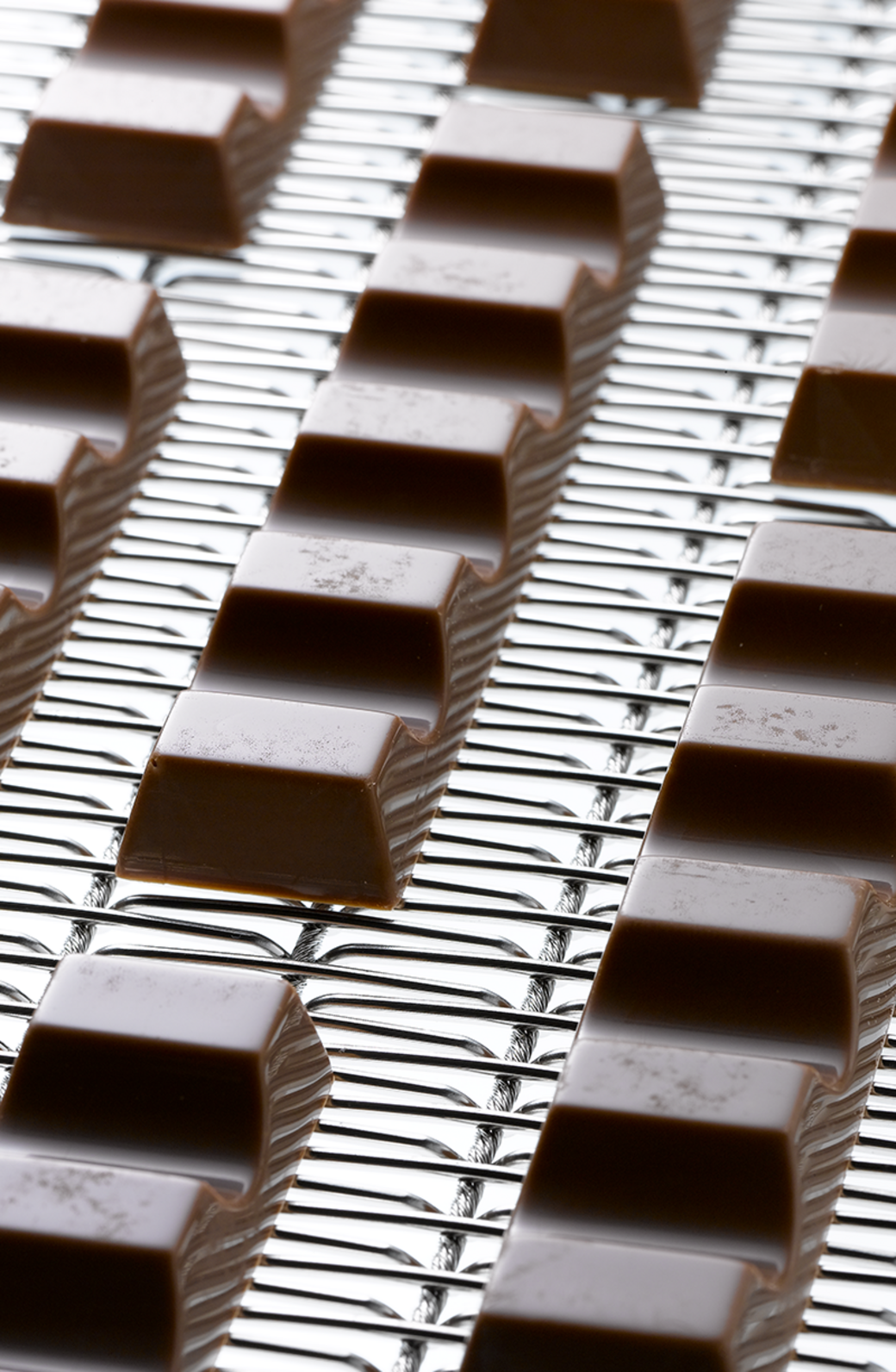

Promote process-reliable, good taste: Woven wire cloth that simply runs better

Our woven wire cloth is convincing in any process. Process belts with our customer-tailored woven wire cloth designs made of metal, plastic or material combinations transport materials or products treated with various processes during transport in food production. Typical application processes are:

- Cooling

- Freezing, shock freezing

- Drying and heat treating

- Heating

- Steaming

- Baking

- Warming

- Dewatering, pressing, filtering

- Washing and cleaning

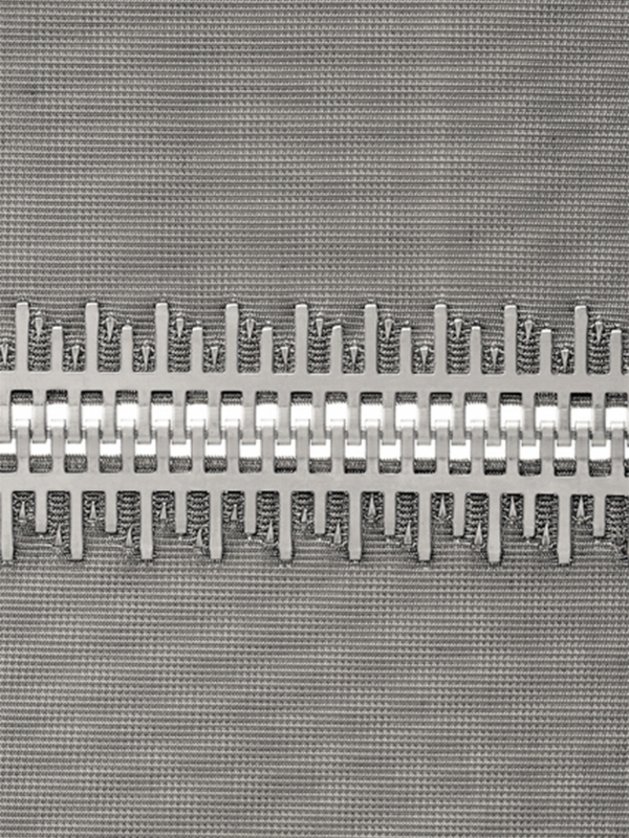

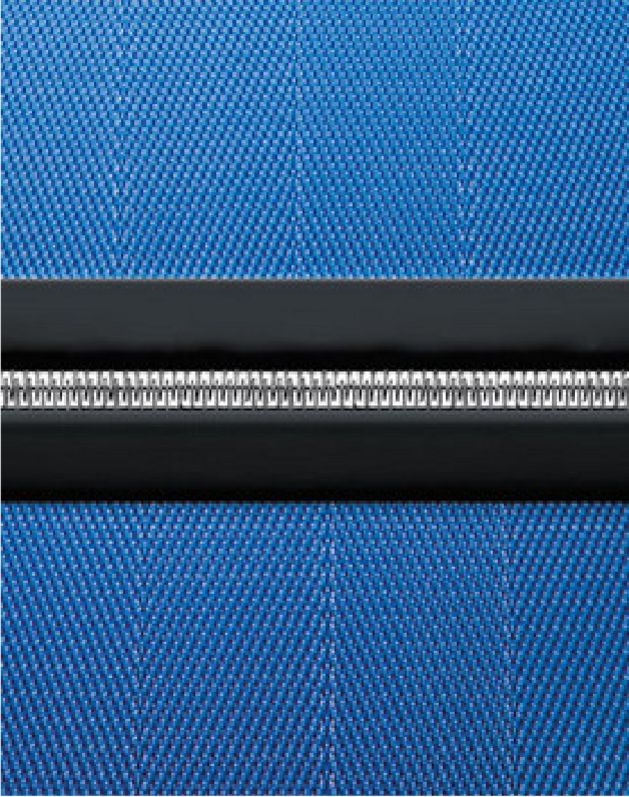

Stainless steel mesh with an alligator seam

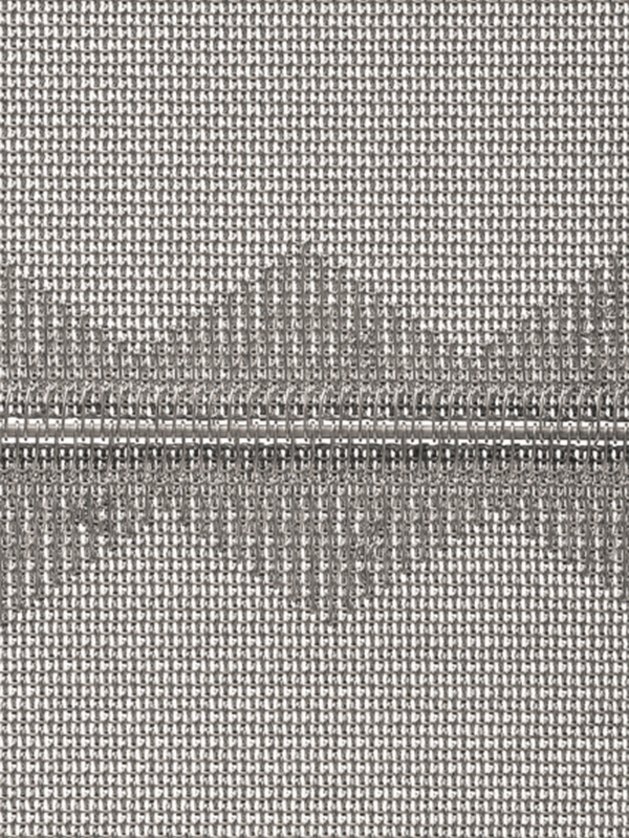

Twisted mesh with a crown pin seam

Nonmarking special seam

Advantages of our process belts

- Manufactured on state-of-the-art looms

- High process performance

- Exactly reproducible results

- High degree of reliability for demanding applications

- Exactly defined individual mesh sizes/woven wire cloth opening/permeability, flow rate/retention capacity

- Heigh lateral stability, optimum flatness, precise tracking

- High process speeds

- Optimised mechanical properties

- High physical and chemical resistance

- High thermal stability

- Approval for use in food processing industry

- Electrostatic safety (ATEX)

- Easy cleaning

- Long life, high running performance

- Delivered ready to install

Twilled weave with a clipper seam

Polyester belt with antistatic wires

PPS belts with antistatic wires

Used for increased productivity

Our woven wire-cloth belts are the first choice for many processes in the food manufacturing and processing – for everything from warming, drying, steaming, baking and heating to cooling, freezing, shock freezing (freezing tunnel, belt freezer, cryogenic technology) and juice production.