Industries

Applications

Wire cloth

Cylinder moulds

Machine construction

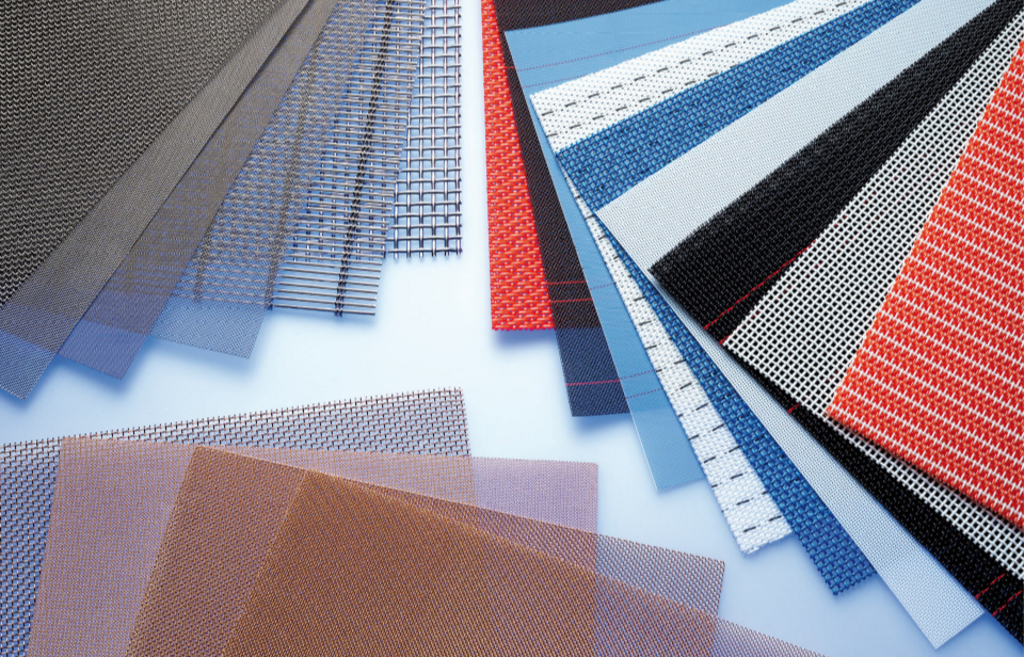

Plastic fabrics and metal fabrics for industry in the highest perfection

Siebfabrik Arthur Maurer GmbH & Co. KG is a fabric specialist for woven fabrics and offers the highest quality in plastic fabrics and metal fabrics for a wide range of industries. The sieves and belts of SIEBFABRIK, headquartered in Mössingen (Baden-Württemberg), are used, for example, in the paper industry, cardboard industry, food industry, fibre cement industry, glass fleece industry and wood processing industry.

Siebfabrik's technical fabrics are made of various metals and plastics: The special blends are used, among other things, in the production of security and banknote paper - Siebfabrik screens are also very popular in aerospace and architectural applications.

Experts for special sieves such as dewatering sieves, press sieves or transport sieves

With around 60 years of experience, Siebfabrik has specialist know-how in many industries for the screens required in each case. These include, for example, dewatering screens for the paper industry, cardboard industry, fibre cement industry and pulp industry. The experts in Mössingen also develop individual solutions for transport screens, press screens, plastic shrink screens and filtration screens, among others.

Production on modern precision weaving machines

As a fabric specialist for sieves, Siebfabrik always uses the latest technologies to meet the customers' requirements to the maximum. The technical fabrics are produced on precision weaving machines. In combination with the in-depth knowledge of the sieve specialists, this results in solutions with which the customers' production processes run efficiently and without interruption at all times. This applies to standard fabrics as well as special fabrics.

Broad product range for fabrics

In addition to the special quality of the sieves, Siebfabrik is characterised by an extraordinary quantity of different fabrics. In Mössingen, for example, fabrics made of all weavable materials as well as fabrics made of stainless steel, fabrics made of non-ferrous metals such as bronze, copper and brass or fabrics made of synthetic materials such as polyester and PPS are produced. Siebfabrik is also known for its woven fabrics in a wide variety of weave types and designs as well as for woven fabrics with weave widths of up to nine metres.

Fabrics for a wide range of applications

Due to the wide range of technical fabrics, Siebfabrik's quality fabrics are used in a wide variety of applications. The functions of the technical fabrics include transporting, dewatering, filtering, forming, drying, heating, cooling, sorting, pressing, designing, decorating and protecting.

In all applications, the plastic and metal fabrics are characterised by their durability: They remain stable even under demanding conditions.

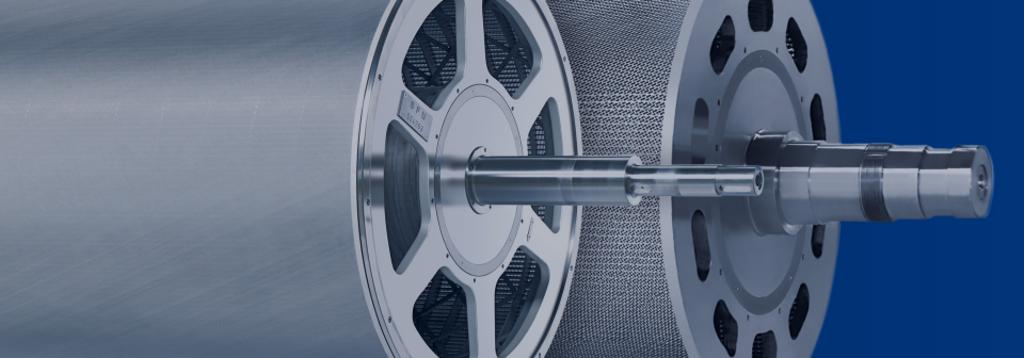

Screen cylinders with excellent performance

In addition to the technical fabrics, SIEBFABRIK's screen cylinders are highly valued: In the mechanical engineering department, SIEBFABRIK manufactures screen cylinders and components for, among others, stock preparation, the paper industry, the pulp industry, for pulp mills, wood grinding mills and waste paper processing plants.

Excellent sheet formation of the wire cylinders

As with the technical fabrics, the expert know-how from Mössingen is also in great demand for SIEBFABRIK screen cylinders in various industries. The G series screen cylinders, for example, operate with a very high concentricity and achieve excellent sheet formation. SIEBFABRIK's customers thus achieve important advantages, for example in cylinder moulders for cardboard machines, in thickeners, stock catchers, as couch rolls in multi-layer Fourdrinier machines or in the manufacture of fibre-cement products.

Unsupported screen cylinders

SIEBFABRIK's F series screen cylinders have a self-supporting design. The advantage for customers is that the cylinder bodies are made of high-alloy stainless steel and do not require any support discs. These SIEBFABRIK screen cylinders are used, for example, in board machines, cardboard machines, thickeners, stock catchers and the manufacture of fibre-cement products.

Comprehensive screen cylinder service

SIEBFABRIK offers a comprehensive screen cylinder service to ensure that the processes run smoothly. The range of services includes, among other things, the application of a new round wire spiral, the application of an edgewise spiral to a perforated shell, the repair or renewal of shaft journals, solder rings and wear rings, as well as the retensioning of screen cylinders.